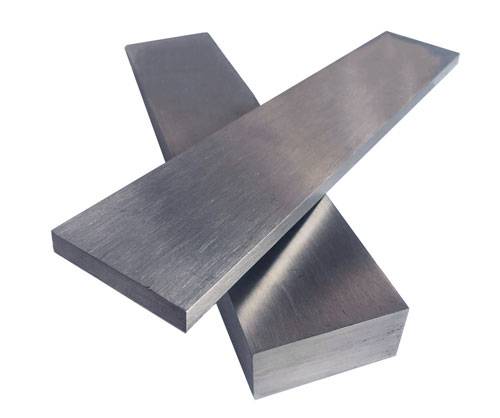

Duplex 2205 Bars, Duplex 2205 Material, Types of Duplex 2205, Duplex 2205 Round Bars, Duplex 2205 Hex Bars, Duplex 2205 Square Bars, Duplex 2205 Bright Bars, Duplex 2205 Flat Bars, Duplex 2205 Forged Bars, Duplex 2205 Manufacturer in Mumbai India, Duplex 2205 Supplier in Mumbai,India.

DUPLEX 2205, also known as Duplex S31803, is a highly sought-after material in metallurgy and engineering due to its exceptional combination of properties. These bars are forged from this specific alloy, a type of duplex stainless steel. Duplex 2205 bars are renowned for their outstanding corrosion resistance, making them ideal for use in harsh environments such as marine applications, chemical processing plants, and offshore oil and gas platforms. Duplex 2205 bars are a versatile and corrosion-resistant material, while SUPER DUPLEX S32750 takes these properties to the next level for even more demanding applications.

Duplex 2205 material exhibits superior pitting and crevice corrosion resistance, often challenging conventional stainless steel. As a result, Duplex 2205 bars offer long-lasting durability, ensuring minimal maintenance and replacement costs over time. Another key feature of Duplex 2205 bars is their high strength, which is significantly greater than that of austenitic stainless steels. This property allows them to withstand heavy loads and high-pressure conditions, making them suitable for various structural and mechanical applications. Moreover, the duplex 2205 structure of this alloy provides a balanced mix of ferrite and austenite phases, contributing to its excellent toughness and resistance to stress corrosion cracking. Whether used in construction, manufacturing, or chemical processing, Duplex S31803 bars offer reliable performance and longevity, making them a preferred choice for many industries.

Duplex s31803 Bars, Types of Duplex s31803, Duplex s31803 Round Bars, Duplex s31803 Hex Bars, Duplex s31803 Square Bars, Duplex s31803 Bright Bars, Duplex s31803 Flat Bars, Duplex s31803 Forged Bars, Duplex s31803 Manufacturer in Mumbai India, Duplex s31803 Supplier in Mumbai,India.

In addition to their exceptional mechanical and corrosion-resistant properties, Duplex bars are known for their cost-effectiveness. This alloy's composition includes lower amounts of nickel than traditional austenitic stainless steels, which helps reduce material costs without sacrificing performance. This cost-efficiency, combined with the bars' durability and versatility, makes the Duplex 2205 bar a smart investment for various applications. Whether you need components for aggressive chemical environments or reliable structural support in demanding conditions, Duplex 2205 bars are a reliable and cost-effective choice.

Frequently Asked Questions

What sizes and forms are Duplex 2205 bars available in?

Duplex 2205 bars come in various sizes and forms, including round, square, hexagonal, and flat bars. The specific size and form you need will depend on your application requirements.

What are the potential challenges when welding Duplex 2205 bars?

Welding Duplex 2205 bars can be more complex than welding austenitic stainless steels. Challenges include the need for precise control of heat input, appropriate filler metals, and post-weld heat treatment in some cases. Proper welding procedures and experienced welders are crucial to ensure the integrity of the welds.

What are the mechanical properties of duplex S31803 bars?

The mechanical properties of duplex S31803 bars typically include high tensile strength, yield strength, and elongation. These properties can vary depending on the heat treatment and size of the bars.

Duplex 2205 / S31803 Round Bars Specification :

Specifications : ASTM A276 / ASME SA276

Dimensions : ASTM, ASME and API

Size : 10 mm To 100 mm Dia in 100 mm TO 6000 mm Length.

Length : 3 to 6 meter, Custom Cut Lengths

Finish : Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish

Form : Round, Square, Hex (A/F), Rectangle, Wire (Coil Form), Wiremesh, Billet, Ingot, Forging Etc.,

Condition : Cold Drawn & Polished Cold Drawn, Centreless Ground & Polished

Duplex Steel 2205 / S31803 Round Bars Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | SAF |

| Duplex S31803 | 1.4462 | S31803 | - |

| Duplex S32205 | 1.4462 | S32205 | 2205 |

Duplex Steel 2205 / S31803 Round Bars Chemical Composition :

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S31803 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 22.0 – 23.0 | 3.0 – 3.5 | 4.50 – 6.50 | 0.14 – 0.20 | 63.72 min |

| S32205 | 0.030 max | 2.00 max | 1.00 max | 0.030 max | 0.020 max | 21.0 – 23.0 | 2.50 - 3.50 | 4.50 – 6.50 | 0.8 – 0.20 | 63.54 min |

Duplex Steel 2205 / S31803 Round Bars Mechanical Properties :

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S31803 / S32205 | 7.805 | 0.285 | 1420 – 1465 | 2588 – 2669 |

Our Export market

Lagos, Vung Tau, Dallas, Petaling Jaya, La Victoria, Coimbatore, Gurgaon, Mumbai, Jamshedpur, Secunderabad, Vadodara, Kuwait City, Dammam, Lahore, Indore, Gimhae-si, New Delhi, Nagpur, Ankara, Ahmedabad, Jeddah, Granada, Navi Mumbai, Al Khobar, Bengaluru, Thiruvananthapuram, Pimpri-Chinchwad, Chennai, Chiyoda, Ulsan, Rio de Janeiro, Muscat, Pune, Chandigarh, Perth, Bhopal, Baroda, Ho Chi Minh City, Sydney, Kolkata, Nashik, Haryana, Howrah, Algiers, Sharjah, Courbevoie, Houston, Al Jubail, Surat, Thane, Tehran, Visakhapatnam, Busan, Ranchi, Madrid, Santiago, Rajkot, Bangkok, Jaipur, Brisbane, Caracas, Hanoi, Kanpur, Cairo, Jakarta, Atyrau, Manama, Ludhiana, Kuala Lumpur, Hyderabad, Faridabad, Noida, Calgary, Istanbul, Ahvaz, Ernakulam, Aberdeen, Bogota, Montreal.

Hong Kong, Hungary, Venezuela, Chile, Portugal, Serbia, Gabon, Colombia, Argentina, Trinidad & Tobago, Egypt, Qatar, Chile, Angola, Libya, Czech Republic, Kazakhstan, Ukraine, Croatia, Pakistan, Norway, Ghana, Russia, Oman, Tibet, Canada, Malaysia, Indonesia, Puerto Rico, Azerbaijan, Bhutan, Thailand, Peru, Sweden, Mexico, Macau, Sri Lanka, Belgium, Mexico, Iran, Zimbabwe, Netherlands, United Kingdom, Gambia, Kenya, South Korea, Poland, Brazil, Algeria, Slovakia, South Africa, Mongolia, Tunisia, Bolivia, United Arab Emirates, United States, New Zealand, Denmark, Philippines, Afghanistan, Poland, Nigeria, India, Costa Rica, China, Nepal, Jordan, Vietnam, Taiwan, Namibia., Bulgaria, Singapore, Japan, Finland, Romania, Turkey, Bangladesh, Yemen, Saudi Arabia, Austria, Iraq, Australia, Spain, Ireland, Iran, Nigeria, Morocco, Lithuania, Estonia, Israel, Kuwait, Italy, Switzerland, France, Greece, Ecuador, Germany, Belarus, Lebanon, Bahrain.